Liquefied Natural Gas (LNG)

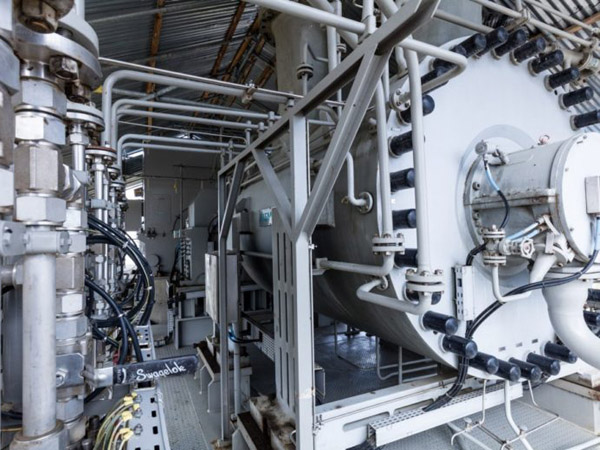

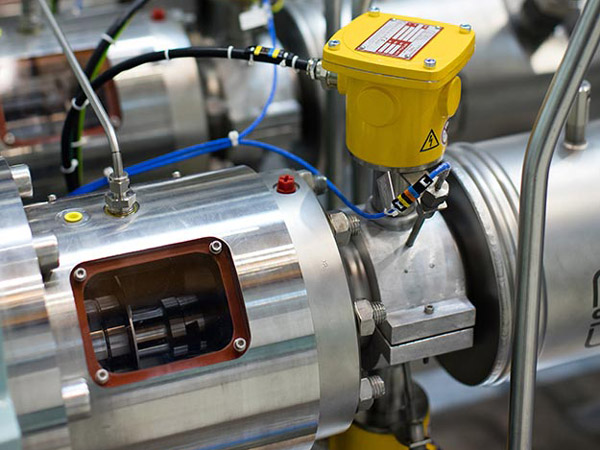

At MARKSAN, our LNG Division provides integrated solutions for the safe storage and management of liquefied natural gas and other cryogenic substances at temperatures from -4°C to -196°C. Our expert engineers ensure compliance with industry standards, guiding clients from design to startup. We focus on hiring and training local personnel while quickly mobilizing construction teams as needed. As a full-service EPC provider, we deliver engineering, procurement, construction, and maintenance services, ensuring optimal performance of all facilities.

Our LNG terminals are essential for storing and transporting liquefied natural gas, featuring specialized tanks and loading systems, along with critical infrastructure like pipelines for efficient distribution. Choose MARKSAN for safe and reliable LNG solutions.

Meet Our Experts

Download Section

| Document Title | Download |

Video Section

| Video Title | Play |

| Liquefied Natural Gas (LNG) value chain...!!! |